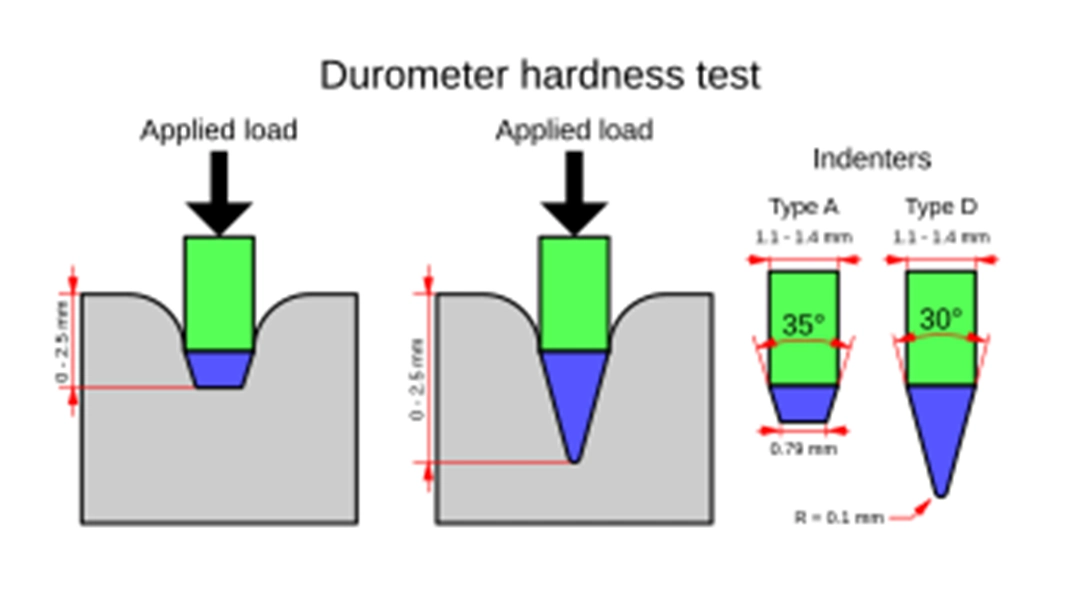

Durometer describes the instrument used to measure hardness, as well as the material’s hardness. Durometer is measured by the depth of an indentation into the material under a standardized force. Softer material will allow a deeper indentation, while harder materials will allow the opposite....

There are several scales of durometer, used for materials with different properties. The two most common scales, using slightly different measurement systems, are the ASTM D2240 type A and type D scales. The A scale is for softer ones, while the D scale is for harder ones. The image of Bareiss digital durometer is shown in the photo. However, the ASTM D2240-00 testing standard calls for a total of 12 scales, depending on the intended use: types A, B, C, D, DO, E, M, O, OO, OOO, OOO-S, and R. Each scale results in a value between 0 and 100, with higher values indicating a harder material.

Common scales used today in casting are Shore A and Shore D. Shore A materials are rubbers, while shore D materials are plastics. Durometers range in scales of 10 with acceptable tolerance of plus or minus 5 points. For example, a shore 60 A material will have a lower acceptable limit of 55 A, and a higher acceptable limit of 65 A.

Types of Durometer scales:

True Value Calibration Services Pvt Ltd.,

#92, S R B Nagar Main Road,

Kolathur, Chennai - 600 099.

Ph: 9710222422/522/622

Cell:9444038060

M/s. TRUE VALUE CALIBRATION SERVICES Pvt Ltd.

No.42, DPF Street, P N Palayam

Near Lakshmi Mills Bus Stop,

Coimbatore - 641 037

Mobile: 9025229719

Ph : 0422-4399816

E-Mail: tvcsplcbe@gmail.com

Web. www.truevaluecalibration.com,